Check Valve

The SCI Corporation commitment to quality and reliability is displayed in the broad range of flanged cast iron Swing Check Valves. Available as simple Swing Check or with optional outside lever with weight or spring assist closure and other accessories.

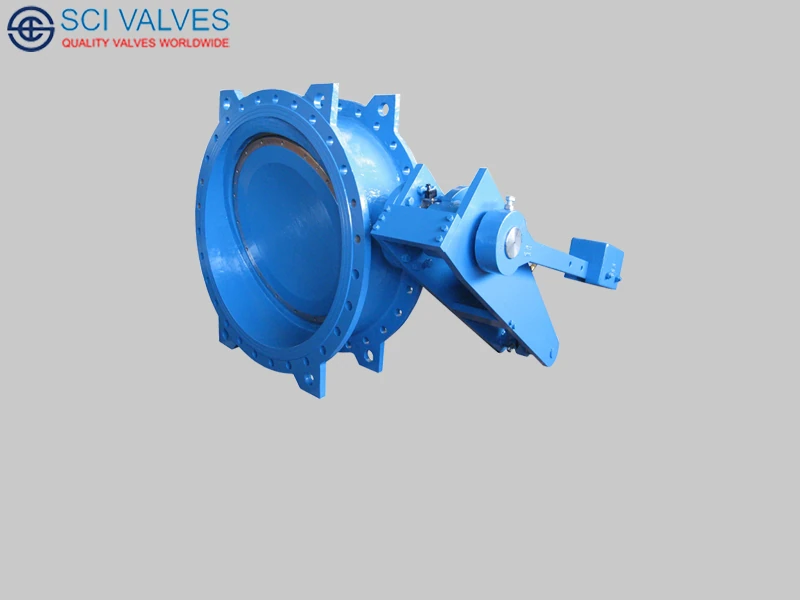

Valves are manufactured and tested in accordance with EN 12334 PN10/16/25, TIS 383 PN6/10/16. MSS-SP-71 class125/250, and also meet the requirements of AWWA C508. The tilting disc and 2 pieces bodies designed check valve accomplishes full flow opening by having the disc pivot or tilt in the flow media. The opening stroke range is much less than those of the conventional swing check valves, therefore reduces opening and closing time critical to controlling flow reversal and reducing water hammer. The full flow areas with lower headloss ensure SCI titling disc check valve will operate with the highest efficiency and durability

- AWWA C-508 size 2”-64” (50 to 1600)

- MSS-SP 71 class 125 size 2”-64” (50 to 1600)

- BS EN 12334 10/16/25 bar DN 50 to 1600

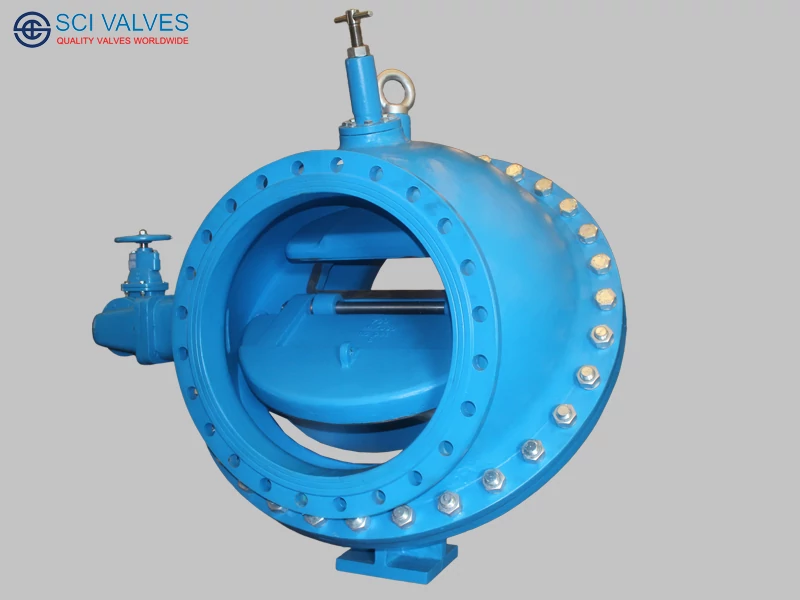

Valves are manufactured and tested in accordance with EN 12334 PN10/16/25, TIS 383 PN6/10/16. MSS-SP 71 class125/250, and also meet the requirements of AWWA C508, generally recommended to prevent backflow with minimum resistance to flow, because of full water way design. Suitable or all types of water, air and steam.

- AWWA C-508 size 2”-80” (50 to 2000)

- MSS-SP 71 class 125 size 2”-80” (50 to 2000)

- BS EN 12334 10/16/25 bar DN 50 to 2000

Valves are manufactured and tested in accordance with MSS-SP-71 class 250 and EN 12334 PN 10/16. The unique design of rubber flapper disc with the hi-strength fabric reinforced which creates an elastic spring effort to close-against the flow, combined with the tilted body seat (closing against 35 degree) act to reduce the closing time, minimize the water hammer and flow reversal. The simplicity in design, three components (Body, Disc & Cover) in one valve, and disc, hinge & hinge pin are integral in one piece with fully special rubber encapsulated offer for maintenance free, 1,000,000 continuous cycles tested with no sign of wear or distortion to the valve disc and seat, Body and Cover are Ductile iron. This valve will operate trouble free for a longer period compared to conventional check valves.

- MSS-SP 71 class 125 size 2”-16” (50 to 400)

- BS EN 12334 10/16/25 bar DN 50 to 400

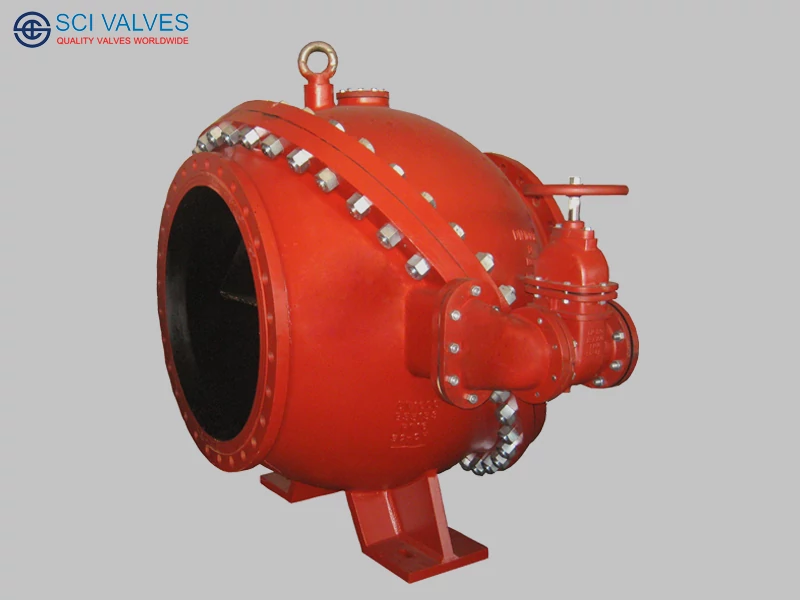

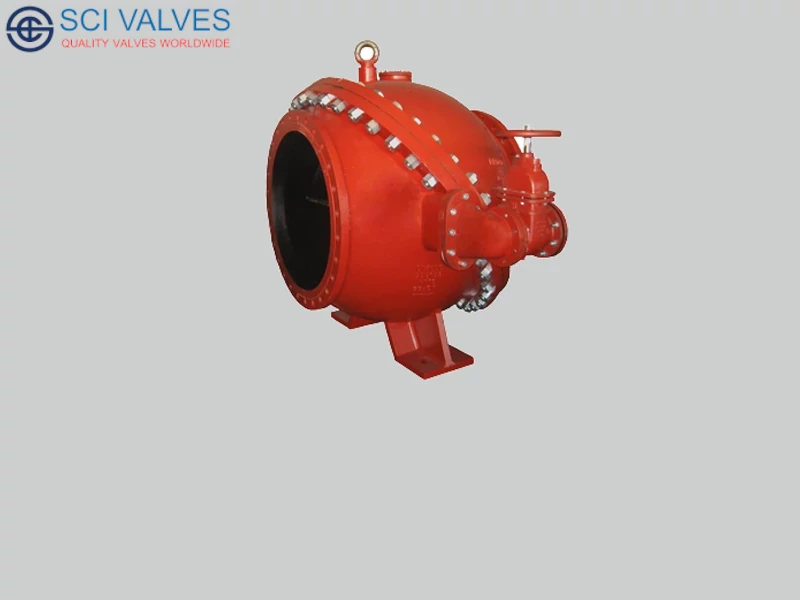

Valves are manufactured and tested in accordance with UL312, FM I210, ULC class 200. The valve designed to offer positive seating for resistance against back pressure or back flow and efficient relax surge in line, suitable for fire protection and distribution service.

- UL Class 175 size 3”–10” (80 to 250)

- FM Class 200 size 2 1/2”–12” (65 to 300)